Advanced driver-assistance systems (ADAS) are developed to improve safety and better driving. To achieve this, these systems require numerous sensors that work cohesively to assess the vehicle and its surroundings, then implement action. ADAS created with automotive LiDAR sensors are the most advanced and efficient forms of this technology.

LiDAR is not new. It’s been used for many purposes, including barcode scanners, image recognition, and creating complex maps to study agriculture and astronomy. Its integration into ADAS features is a recent development in the last decade.

LiDAR has revolutionized ADAS, helping to create more advanced systems with even greater safety capabilities. But, how does this technology work? And will the advantages of ADAS LiDAR lead to the replacement of traditional ADAS technology like radar and camera sensors?

What is ADAS LiDAR?

Light Detection and Ranging (LiDAR) is a remote sensing technology that uses a pulsed laser to detect surrounding objects with an extremely high level of accuracy.

This technology is enormously advantageous in the development of ADAS because it has a much greater range than camera and radar sensors.

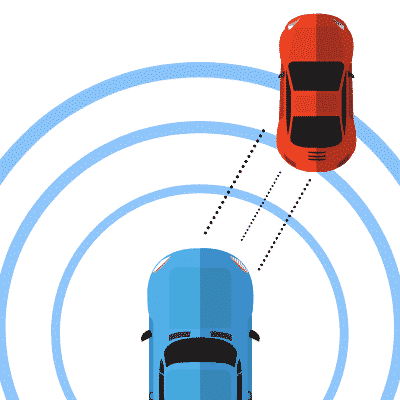

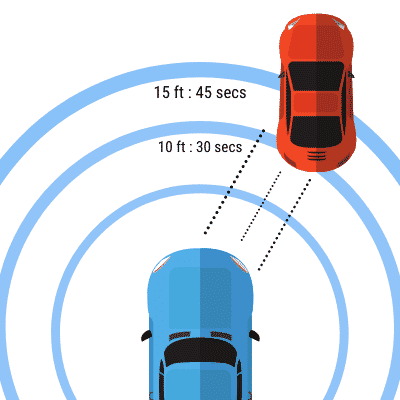

So how exactly do ADAS LiDAR systems work?

For simplicity, these diagrams use images of another car as a surrounding object, but Lidar sensors have the capability and precision to discover much smaller obstructions. For example, they can also sense pedestrians and irregularities in the terrain. Lidar can detect non-stationary objects in real time by emitting billions of light photons every second. The technology still works in the dark, which gives it an advantage over camera sensors.

Types of ADAS LiDAR Systems

Electromechanical Lidar

Traditional LiDAR systems are electromechanical. They have moving parts and can be quite large. Google’s self-driving car featured a 64-laser electromechanical LiDAR sensor that sat on the roof of the vehicle. It spins to give a 3D image of the vehicle’s surroundings using the lasers. This particular system is highly complex and cost $75,000. Affordability isn’t the only issue with electromechanical systems, the size, placement, and number of moving parts leave room for more damage to occur.

Solid-State Lidar

In recent years we’ve seen LiDAR sensors completely evolve. Solid-state LiDAR systems are built on a semiconductor device that has no moving parts. Generally speaking, they are much smaller than traditional systems and some have been built onto a single, tiny chip. Solid-state LiDAR is also lower cost, while still providing high performance and reliability.

ADAS Sensor Cohesion

Although LiDAR technology is the most advanced and has the greatest performance of ADAS sensors, it hasn’t replaced camera, radar, and sonar sensors yet. The truth is that there are benefits to all of these sensors and each of them has unique vulnerabilities.

Cameras lose some of their functionality in low-light or at night. Radar has an impressive range, but it loses resolution as that range expands. LiDAR is the only sensor that gives impressive resolution with a large range.

On the other hand, current LiDAR technology does not have the same resolution as a camera. While radar systems function in poor weather more efficiently. Because of these disadvantages, many ADAS utilize more than one type of sensor. The hope for the future is that ADAS LiDAR continues to innovate, providing more capability without the drawbacks.

What’s driving the change?

ADAS are already commonplace in the current consumer market. Over 60 million vehicles in the United States have this technology. We’ve seen incredible changes come from their implementation. A study analyzing rear-end crashes, conducted by AAA, determined that ADAS features have the potential to eliminate 2.3 million crashes and 7,166 fatal crashes in a four-year period . It’s expected that these benefits will become even more widespread as higher-quality sensors are developed.

There’s been a huge influx in recent years of LiDAR companies coming on the market, with hopes that manufacturers will begin to utilize ADAS LiDAR technology on a larger scale. More than 50 LiDAR sensor manufacturers are experimenting with development and competing for the market. Some OEMs, such as Toyota and Volvo , have fostered partnerships with LiDAR companies and will begin to install these sensors across high and mid-range priced vehicles.

How ADAS LiDAR Is Affected by Repairs and Vehicle Modifications

Even though LiDAR is one of the most advanced ADAS sensing technologies available, its accuracy depends heavily on proper alignment, positioning, and calibration. Any change to the vehicle that alters sensor placement or vehicle geometry can impact how LiDAR interprets its surroundings

Common situations that can affect ADAS LiDAR performance include:

- Front-end collisions or minor impacts

- Bumper, grille, or body panel replacements

- Suspension repairs or ride-height changes

- Windshield or roof component replacements on vehicles with integrated sensors

Because LiDAR creates a precise 3D map of the environment, even small misalignments can lead to inaccurate distance measurements, delayed object detection, or false alerts. These issues may not always trigger a dashboard warning, making post-repair calibration critical for ensuring the system operates as intended.

The Cost of Lidar Advancement

In the past, LiDAR technology has been associated with luxury price tags. However, LiDAR technology is becoming much more affordable and continues to reduce in price as it gains popularity. We’ve already seen a decrease in price from an average of $50,000 to below $10,000 . Some experts predict that LiDAR modules will cost less than $200 by 2022.

Today, there are still expensive ADAS LiDAR sensors on the market but there are also lower-cost options. This January, industry leader Velodyne announced a $100 LiDAR unit called Velabit . This compact sensor is less than 2.5” all the way around and offers an impressive 100-meter range.

Luminar is another company that has recently garnered attention for its more affordable technology. Their partnership with Volvo includes an Iris LiDAR unit for vehicles seeking full autonomy that costs less than $1,000 to produce.

Looking at the current market, it’s clear that leading players are gunning for LiDAR that can be mass-produced in an affordable price range. While it may take time, it’s an inevitable move in a competitive market.

The Road Ahead for Automotive Lidar

The race for powerful, reliable, and affordable ADAS LiDAR sensors has already begun. As it continues, we’re seeing immense benefits to driver and pedestrian safety. Mass production of LiDAR systems will reduce collisions from human error beyond what we’re already experiencing from advanced driver-assistance systems as a whole.

One of our core values at CarADAS is to remain on the cutting edge of ADAS technology. We already have the ability to calibrate early ADAS LiDAR systems and we believe that the continued adoption and improvement of LiDAR is making the world a safer place to drive.

Contact Car ADAS today for Utah ADAS calibration or calibration center licensing opportunities.

Read more in our ADAS blog or ADAS Sensor Guide.

LiDAR FAQs

What makes LiDAR different from other ADAS sensors?

LiDAR uses laser pulses to create highly detailed 3D maps of a vehicle’s surroundings. Compared to cameras and radar, it provides stronger depth perception and higher accuracy over longer distances, especially for detecting objects like pedestrians and road hazards

Can ADAS LiDAR work in the dark or low-light conditions?

Yes. LiDAR does not rely on ambient light. Because it emits its own laser pulses, it functions effectively at night and in low-light environments where camera-based systems may struggle

Does LiDAR replace cameras and radar in ADAS systems?

No. Most modern ADAS platforms rely on sensor fusion, meaning LiDAR works alongside cameras, radar, and sonar. Each sensor has strengths and limitations, and combining them improves overall system reliability and safety